The parallel axis reducer is composed by a G 25 cast iron box and by cylindrical gears with 16CrNi4 steel helicoidal teeth, reinforced and rectified in order to reduce the noise during functioning. The axial bearing is proportioned on each size, in order to guarantee a perfect resistance to axial and radial loads.

Standard cylinders and screws assembled on our semi-extruders are made of 41 CrAIMo7 steel, nitrided with vertical gas nitride process for 72 h, class NT5, reaching a final hardness of HV 900-1000. The cylinder is internally striped around the hopper hole area, in order to obtain a better material load.

It is also possible to assemble special groups with bi-metallic cylinder (anti-scraping, anti-corrosion or with both features) and cap or reported screw with special alloys, different from one another according to the applications needs.

The profile and geometry of screws are designed taking into account the material to be worked, in order to obtain the best result in terms of plastification and performance.

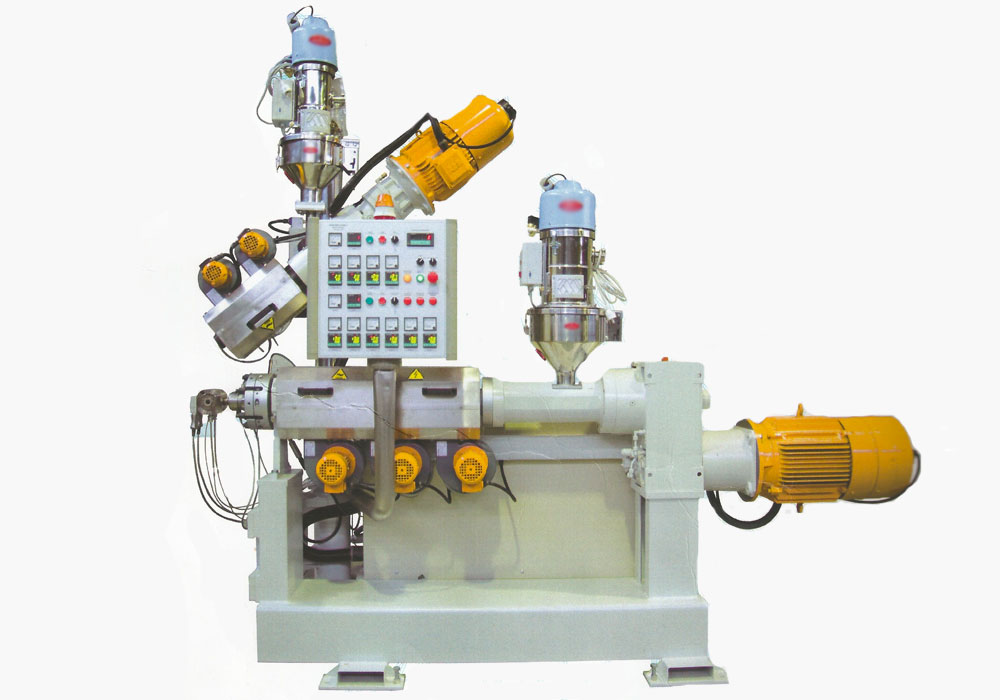

Extrusion unit consisting of:

a single-screw extruder driven by motor A.C., quality gear, cooling socket with internal compass interchangeable grooved, plasticizing cylinder screw LK3 nitrided and profile according to type of material.

The temperature control unit with ventilated resistors and dumpster in stainless steel, the closure flange to book where to mount the extrusion head, the load of material hopper with quick exhaust, co-extruder unit mounted on column directly on the base with the possibility to have various configurations depending on the use of the extrusion head.

Machina back of the electrical panel containing vector inverters and electrical components, the mobile front control panel.

There are two versions known as:

COMPACT P for plastic material

COMPACT R for rubber and silicone

With the water temperature controllers, temperature-controlled screw, loading mouth with roller power strip and its protection.